Post Harvest Maintenance Tips

Check your corn head now for optimum harvest performance this fall.

Evaluating your corn head for the next harvest season should begin during harvest in the current season, according to Fenton, Iowa farmer and Dragotec President, Denny Bollig. “That’s when you have the best opportunity to determine its condition, how well it is performing and whether the machine has another year or more of performance left.”

Simple maintenance can help capture more yield and extend the life of your corn head.

“Considering today’s farm equipment supply chain issues — and rising equipment costs — taking good

care of your equipment can return significant cost savings,” says Bollig.

“And while the combine once was the primary focus for fall service, producers understand the importance of maintaining the corn head, too.” Bollig refers to an Iowa State University study that suggests that more than 60% of the corn lost during harvest occurs at the corn head.

Proper maintenance of the corn head not only can extend its life but help reduce harvest loss in the seasons to come.

Harvest considerations

“Good management and good maintenance go hand in hand,” says Bollig. “And while factors such as build quality, weather and acres harvested can also affect the lifespan of a corn head, it won’t last unless properly maintained.”

He cites key areas of your corn head to review post-harvest include deck plates, knife rollers, the drive system and gearboxes. Whether you do maintenance immediately after harvest or during the winter, identifying components that need to be addressed now will help avoid potential costly surprises next season.

Check deck plates

“Deck plate alignment is critical to getting more yield acre after acre,” he says. “Over time, debris, linkage wear and field obstacles can cause hydraulic deck plate gaps to deviate among row units from the original factory-set calibration.”

He notes that Drago corn heads with automatic self adjusting deck plates don’t require calibration and provide more self-cleaning action from constant movement.

Inspect knife rollers

Harvesting high-yielding corn requires consistent feeding action at the knife rollers. Although this may seem like an obvious maintenance checkpoint, Bollig says farmers often overlook knife roller wear and spacing, which can cost yield.

“Worn knife rollers can create stalk slippage during pull-down and require higher speeds to process plant material,” says Bollig. “And a consequence of a higher knife roller speed is an increase in yield loss via butt shelling and ear loss.”

He adds that most knife roller designs have a short window to fully process stalks. Inefficient stalk processing means stalks can bunch up. “Farmers naturally compensate for this by increasing roller speed but in doing so, are creating additional wear in a concentrated area at the front of knife rollers.”

Overlooking knife roller maintenance — or having to change knife rollers during the harvest season — can add significant time and cost on top of yield reductions. It’s important to be proactive and not try and press your luck going into harvest.

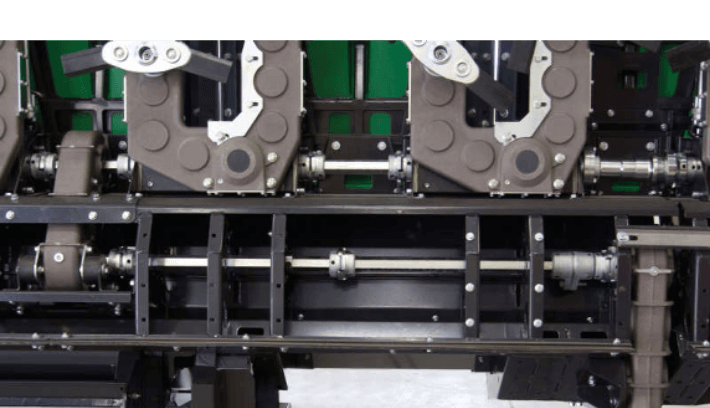

Drive system and gearboxes

Other maintenance trouble spots include corn head drive system components. Inevitably, as chains, sprockets and gears wear, drive system components lose efficiency. In addition to examining the drive system for signs of wear, producers should also check both the level and condition of the manufacturer’s specified lubricant in each row unit gearbox.

“Gearboxes are at the heart of any corn head, and their wear can be a great indicator of its longevity,” says Bollig. “Producers might consider replacing their corn head when major drive components, including row unit gearboxes, begin to fail or when there is excessive backlash movement of rotating shafts and sprockets.”

Other maintenance considerations

Referencing the operator’s manual is always a good way for producers to bring themselves back up to speed on the proper maintenance of their corn head. Other routine corn head care procedures include:

- Clean the corn head as thoroughly as possible after harvest – without water – removing dirt and debris to prevent caking, moisture collection and corrosion.

- Maintaining normal or severe service lubrication schedules to help avoid breakdowns.

- Clearing and blowing trash from all areas it has collected through harvest — under deck plates, cones, under bonnets, etc., to keep all parts moving freely.

- Cleaning gathering chain tensioners regularly. Proper tension adds life to chains and sprockets.

- Cleaning and checking roller blades for wear and potential replacement, check auger, chains, etc.

- Inspect every part of the corn head – check overall condition, check stalk rollers for wear, chains for looseness, make adjustments where needed, oil and tighten chains where needed.

- Check lube levels and bearings. Inspect gearboxes and look for seal leaks.

Repair or replace

Bollig says producers must use their discretion when weighing the cost of repairs versus replacement. “When making a decision about part replacements, ask, ‘What is it going to cost’ without just thinking about the cost of the part itself,” Bollig advises. “Producers must weigh potential repairs and potential downtime with the cost and performance of a new or good used corn head,” Bollig says.

“And any decision to purchase a new corn head should be made immediately following harvest,” Bollig advises. “That’s when you’ll find the most choice, the greatest selection and best price.”