When Mother Nature is at her worst, a Drago is at its best.

“The yield that Mother Nature delivers isn’t yours until it’s in the grain tank,” says Fenton, Iowa, farmer and Dragotec USA President Denny Bollig. “Even with the best genetics and the most modern, efficient equipment, there’s still plenty of opportunity to lose yield.

“It’s important to plan ahead, be realistic about all the variables, and have a corn head that can react instantly for you.”

Bollig believes that a Drago corn head, with unique features, including automatic, self-adjusting deck plates, aggressive overlapping gathering chains, and QuadSuspension™ with integrated “ear shocks” placed under deck plates, is uniquely capable of maximizing yield in less-than-ideal harvest conditions.

He describes some of the yield-stealing conditions and how a Drago corn head is built to deal it them.

Down corn

Down corn is one of the greatest fears for producers at harvest, Bollig notes. “All the sins of the growing season show up at harvest. Excessive moisture can force us to till and plant in conditions that are not ideal, impairing root development from tillage and sidewall compaction. Add to that potential plant disease, insect problems and windstorms, and your chances for down corn increase dramatically.”

The location of gathering chains and their ability to grab and gather leaning stalks are crucial in picking up down corn. Bollig points out that Drago gathering chains, by comparison to other brands, are located out-front and overlap to grab and secure stalks.

“And Drago choppers are positioned behind the knife rollers to avoid striking leaning plants, which can prematurely drop ears before plants can be processed.”

He also points out that Drago corn heads feature the lowest profile in the industry, allowing them to slip through down stalks and better retain falling ears.

Stalk variability

Many producers don’t realize the amount of stalk variability there is, or the role it plays in yield loss, Bollig notes. “We’ve conducted multi-year harvest studies showing that there is significant variability in stalk size entering every row of the corn head at any given time. One of the more surprising things we’ve learned is that the variability in stalk size actually increases with yield — taking a significant jump at 200+ bu./acre, which is contrary to what most producers believe.”

The inability to manually adjust deck plates to compensate for this variability can be a significant source of yield loss at harvest, Bollig says. He points to Iowa State University research that shows a deck plate gap as little as a 1/8 inch wider than required can mean up to a 4 bu./acre loss in the field. *

“Because of plant variability and limited visibility, it’s really impossible to accurately set deck plates from a combine cab at harvest,” he points out. “Operators can’t see when deck plates are set too wide, and when the deck plate gap is too tight, excessive plant material is run through the combine, causing yield loss there.”

He points out that Drago corn heads keep those gaps to a minimum with independent, self-adjusting deck plates that automatically adjust to stalk variability – both in-row and row-to-row.

Kernel moisture

Harvest loss from kernel moisture can be extreme at the beginning of the harvest season when corn moisture is high, as well as later in the season as corn dries down.

“Harvest is a violent process,” Bollig says. “A primary contributor of yield loss at the corn head is related to the speed at which stalks are pulled down onto the deck plates.”

Early in the harvest season, higher-moisture ears can bounce off deck plates, and butt shelling can be significant in drier corn – especially considering today’s fast dry-down genetics – for the same reason.

“Dry ears have built-in shock absorbers; they’re called kernels,” Bollig jokes. “Upon impact those dry kernels shell and can be lost.

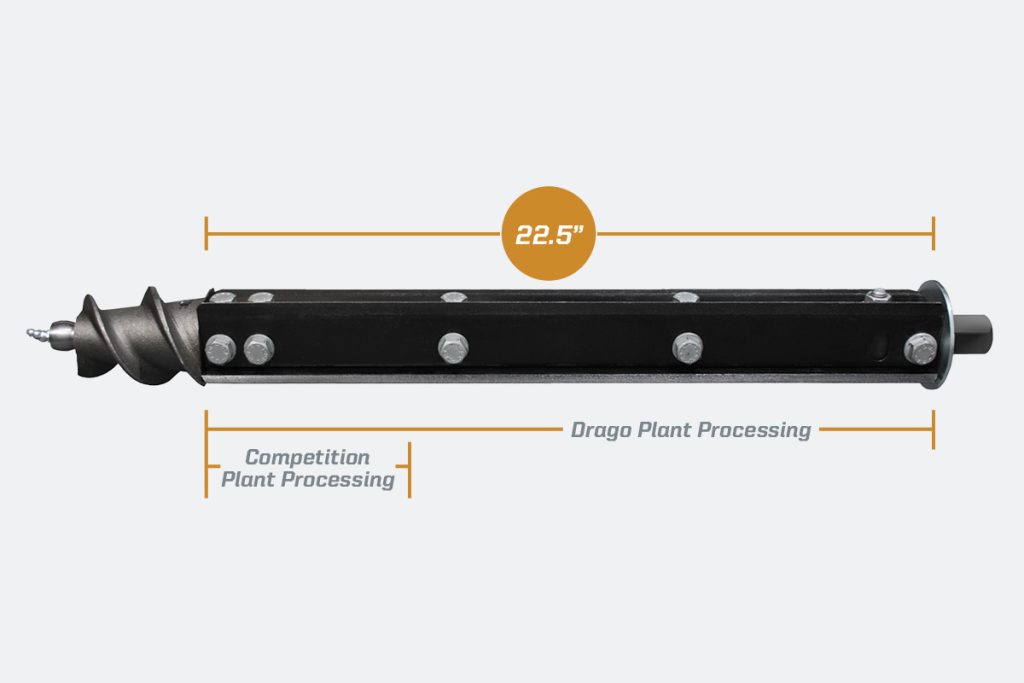

“Drago knife rollers are the longest in the industry so they can run slower. Their length gives them added time for processing. Of course, the slower speed reduces the velocity of ear impact – and ear bounce – off deck plates.”

He points out that the Drago GT corn head also features “ear shocks” placed under deck plates to help absorb ear impact. The feature, called QuadSuspension, helps reduce ear bounce as well as kernel loss.”

Choosing the right corn head

“The ability of a corn head to reduce loss at harvest has a lot to do with the genetics producers choose at planting,” Bollig says. “As farmers, we balance traits like faster dry down, ear retention and standability with potential yield. Plus, we are continually pushing plant populations to increase corn yield. The result is that we risk plant vulnerability to weak stands, kernel loss with fast dry down, and loss of smaller ears – which can slip through deck plates.

“Producers shouldn’t change their genetics and sacrifice higher yields due to concerns of higher loss, but they should consider owning a corn head that can compensate for the potential issues their genetics – and Mother Nature – may bring.”

*Graeme Quick field research, Iowa State University.