GEARBOXES BUILT FOR THE JOB

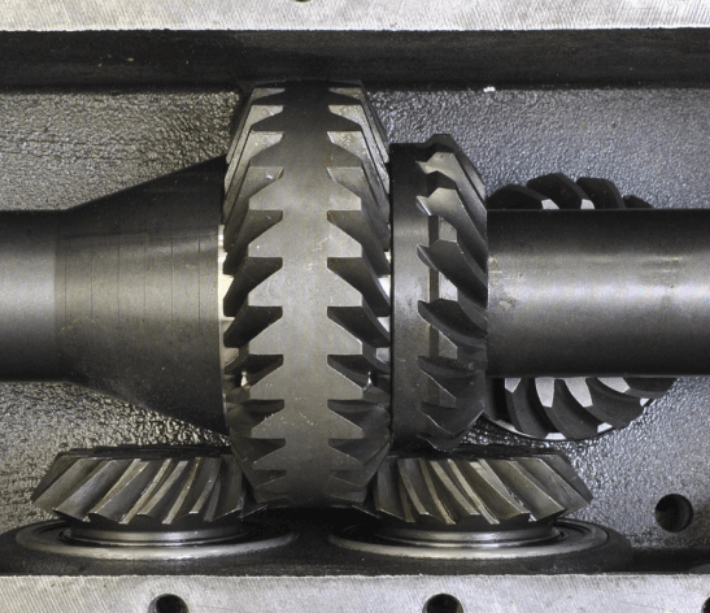

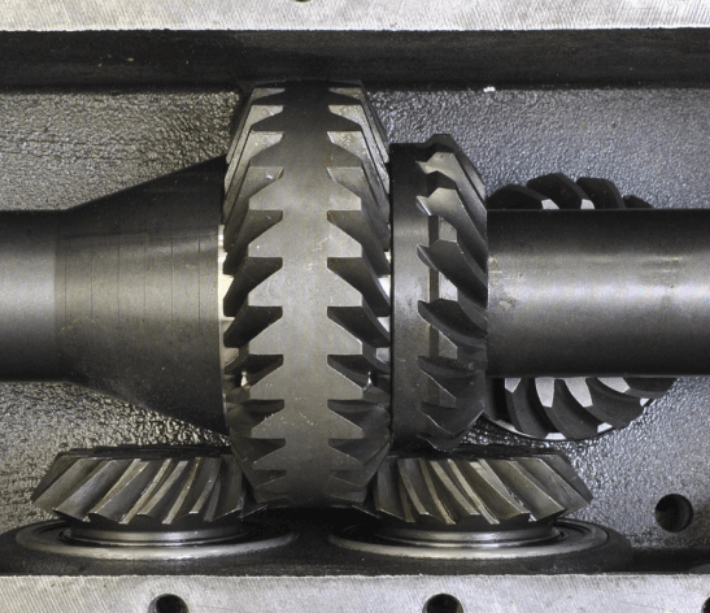

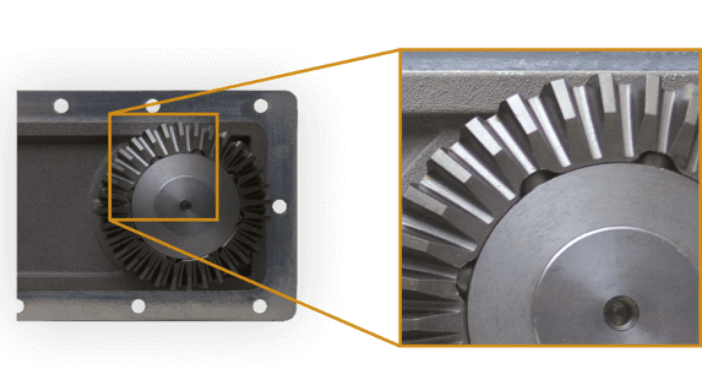

Nothing says durability like a Drago gearbox. Along with its exceptionally robust bull gear are the industry’s first spiral-bevel gears. Designed for high speed and high-torque power, Drago’s spiral-cut gears engage more than one set of teeth for a significantly stronger load bearing surface and more efficient load transmission. Drago spiral-bevel gears deliver a smoother, quieter, longer-lasting performance with minimal need for repairs or replacements.

PRECISE CLUTCH TECHNOLOGY

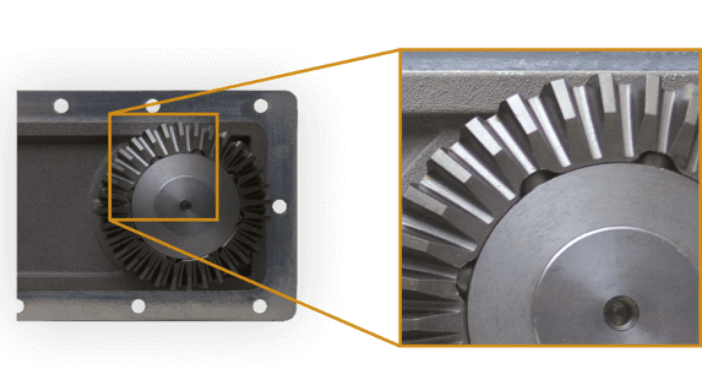

Drago GT is the first corn head to feature a radial slip clutch design with four different operations within each row unit. Both gathering chains, knife rollers and chopper gearbox each have their own dedicated slip clutch compared to the one-clutch-for-all approach of our competition. Rather than a single clutch set for the highest load setting, individual components with their own precise, protective setting means greater harvest reliability and significantly reduced potential for unwanted breakdowns and cost.

“Gearboxes are at the heart of any corn head, and their

wear can be a great indicator of its longevity,” says Bollig.

“Producers might consider replacing their corn head when

major drive components, including row unit gearboxes,

begin to fail or when there is excessive backlash movement

of rotating shafts and sprockets.”

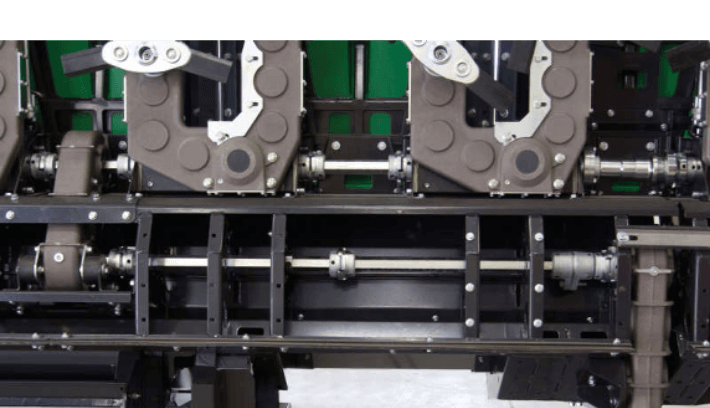

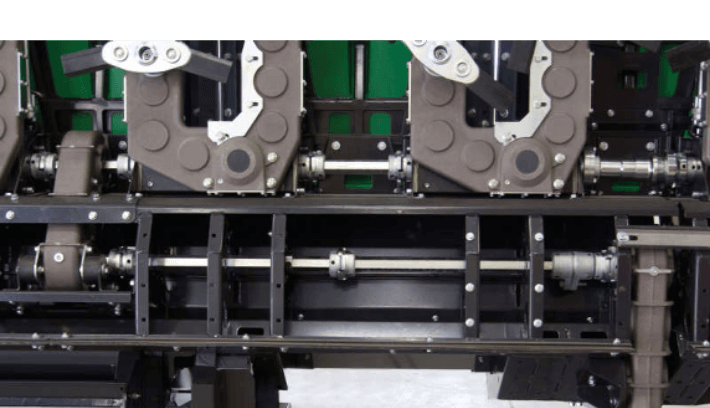

CHAINLESS DRIVE RELIABILITY

The Drago GT features the first chainless design — including the auger drive — that’s standard on all row configurations. Power is delivered through a simple inline design, called Endura Drive™, that transfers power directly through each row unit — eliminating two gears per row compared to our competition — for greater efficiency and durability. Drago gear-driven inline power and auger drives deliver long-lasting, virtually maintenance-free performance and reliability.

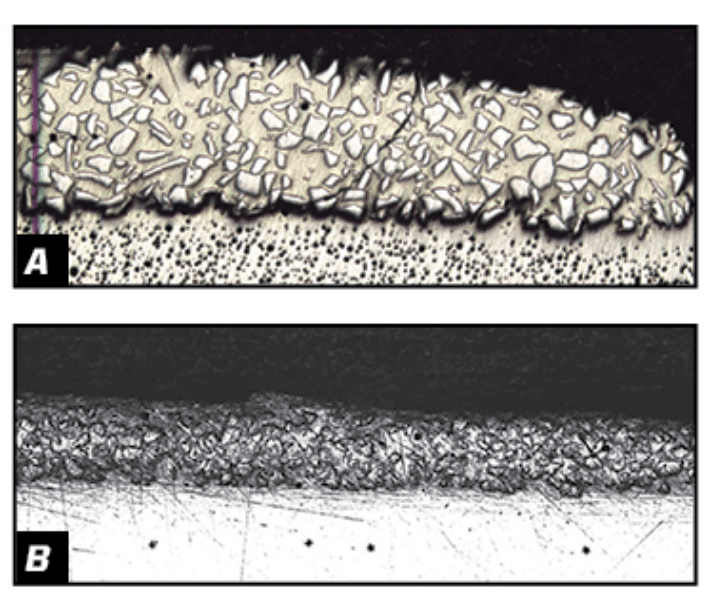

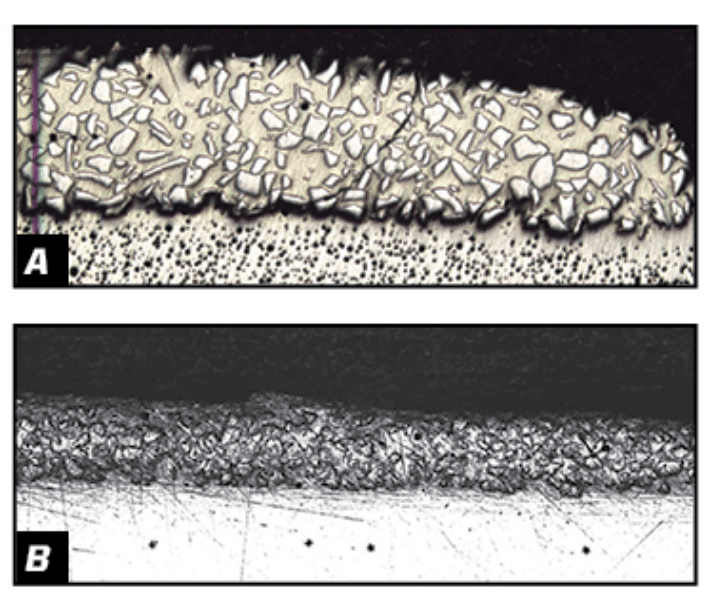

Top image (A): Major OEM blade with inconsistent application of tungsten.

Bottom image (B): "Drago blade with uniform laser-applied tungsten edge.

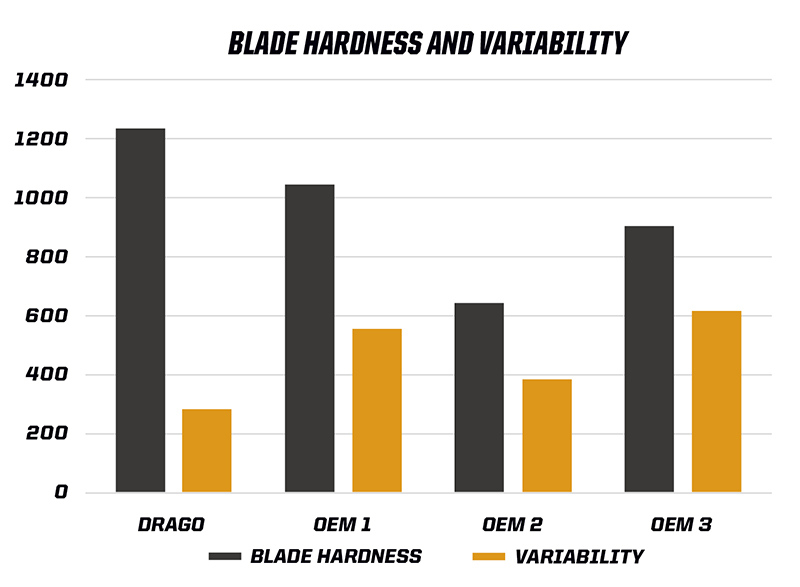

LONGER-LASTING KNIVES AND BLADES

A commitment to durability extends to the performance of our roller knives and chopping blades with laser-applied tungsten, called EnduraClad™, to their working edge. Other brands apply tungsten to their knives with adhesives — a comparatively cheaper, low-tech process. Along with higher-quality steel, our metallurgical tests reveal that Drago’s laser-applied tungsten coating is denser and more consistent than those of either John Deere or Case IH. An even and consistent tungsten application is significant because it reduces areas of weak spots that subject knives to faster wear. In other words, the durability of a blade is only as good as the weakest point of its coating.