Stalk Variability & Harvest Loss

We know that sixty percent of yield loss during harvest occurs at the corn head. But how?

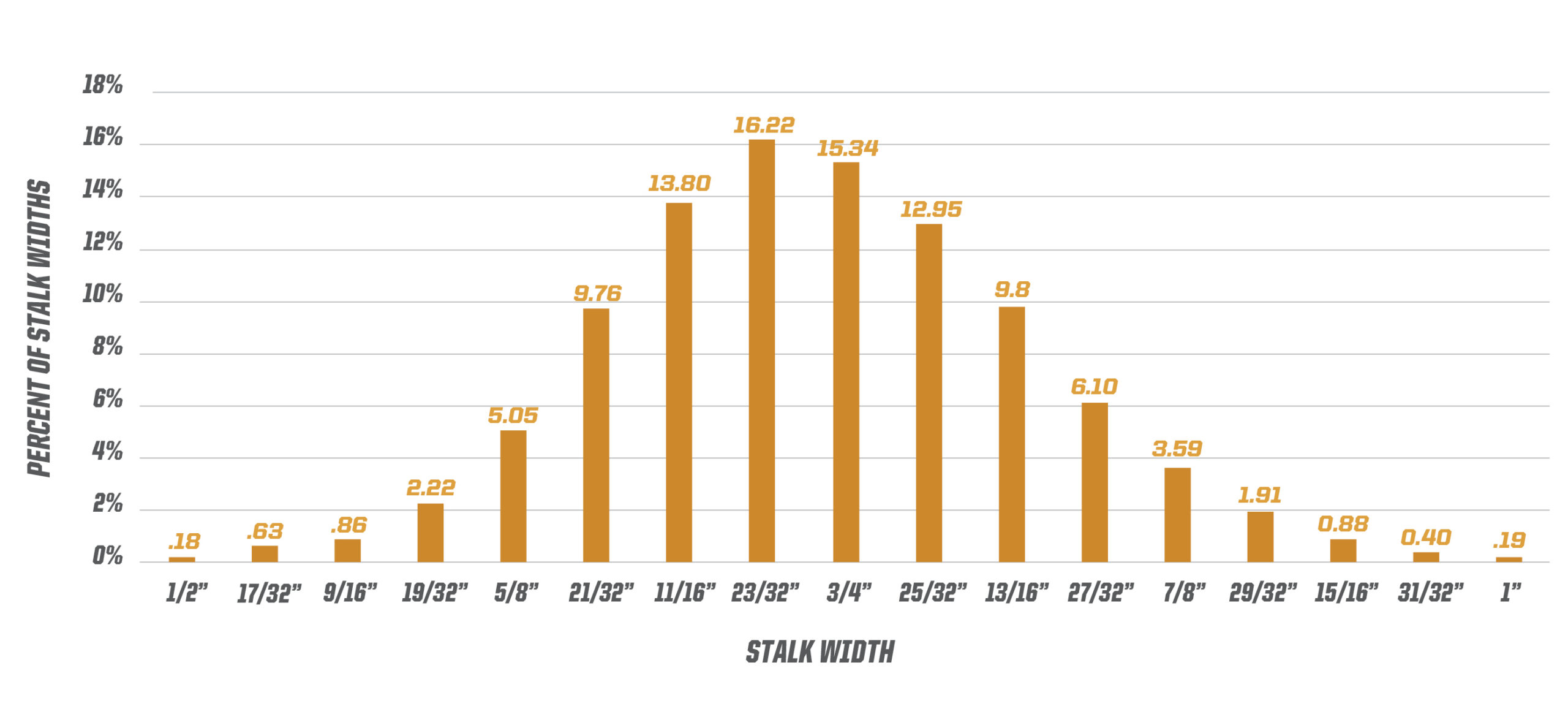

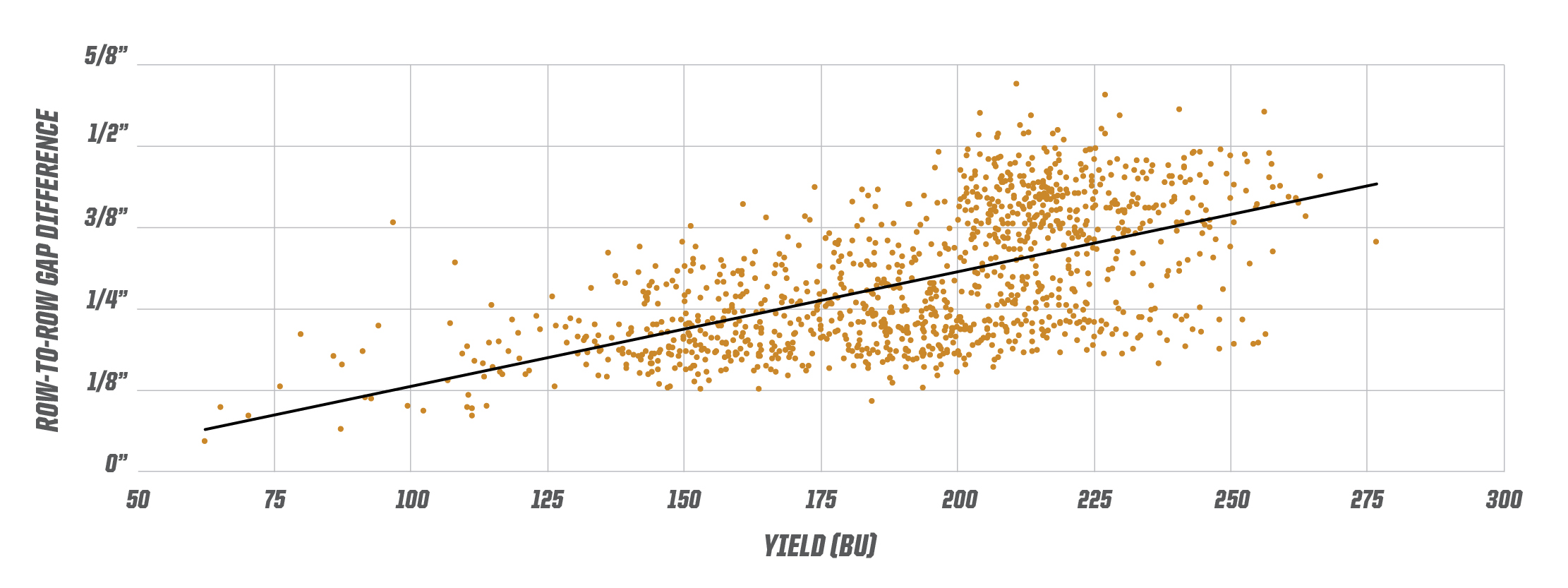

A multiyear study found that stalk variability increased with yield, especially in 200-bu. and higher yield environments.

“Multiyear, on-farm harvest research confirmed a direct correlation between stalk variability and yield,” says Dustin Bollig, farmer and vice president of sales and marketing for Drago. “And it isn’t what most people think: as yield increases, so does variability.”

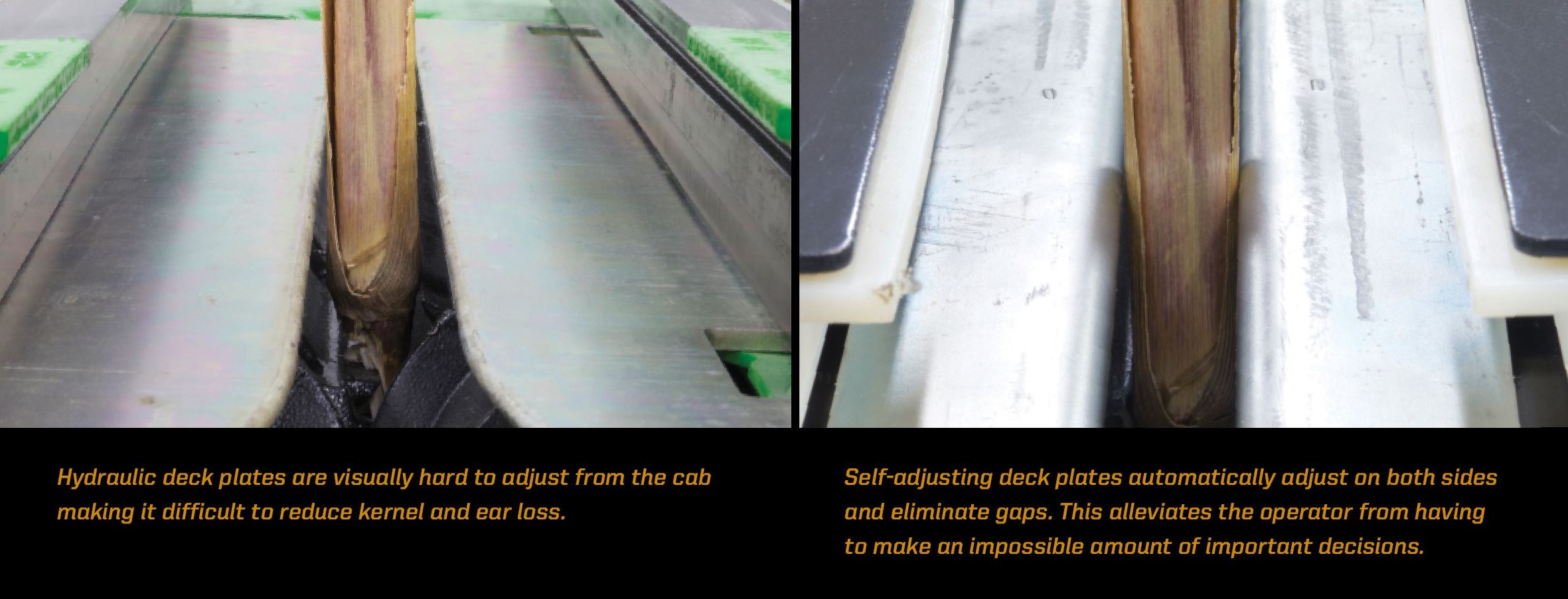

Along with ear bounce, studies have shown that deck plate gaps as small as 1/8 inch between plants and plates can result in a one to four bushel per acre loss. *

“Your best fields have the highest potential kernel loss.”

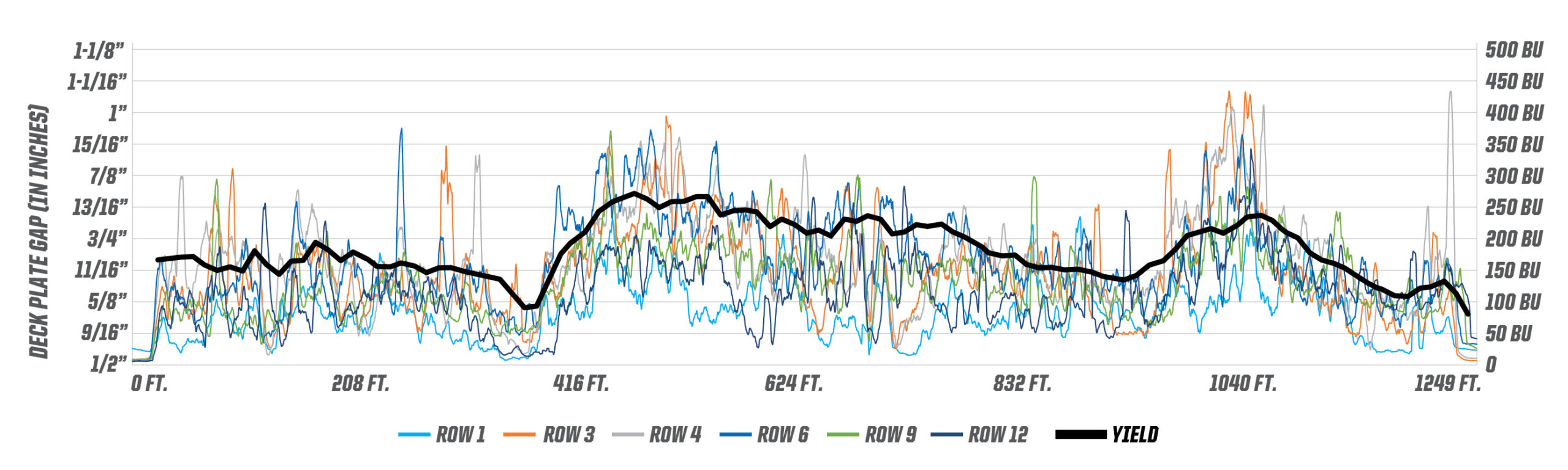

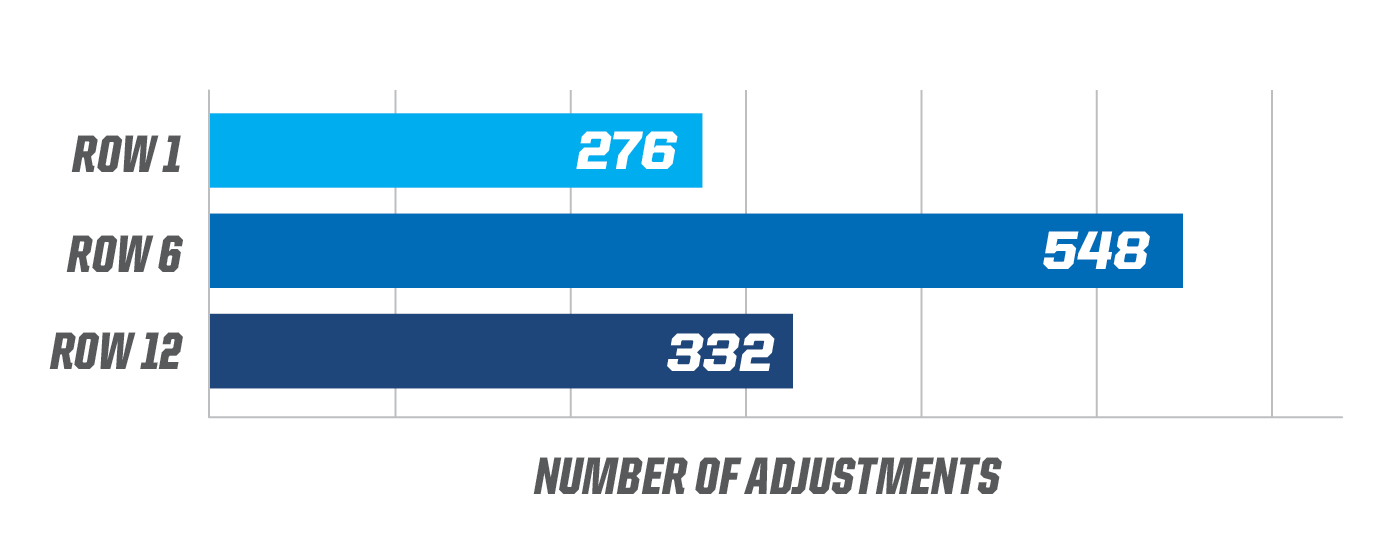

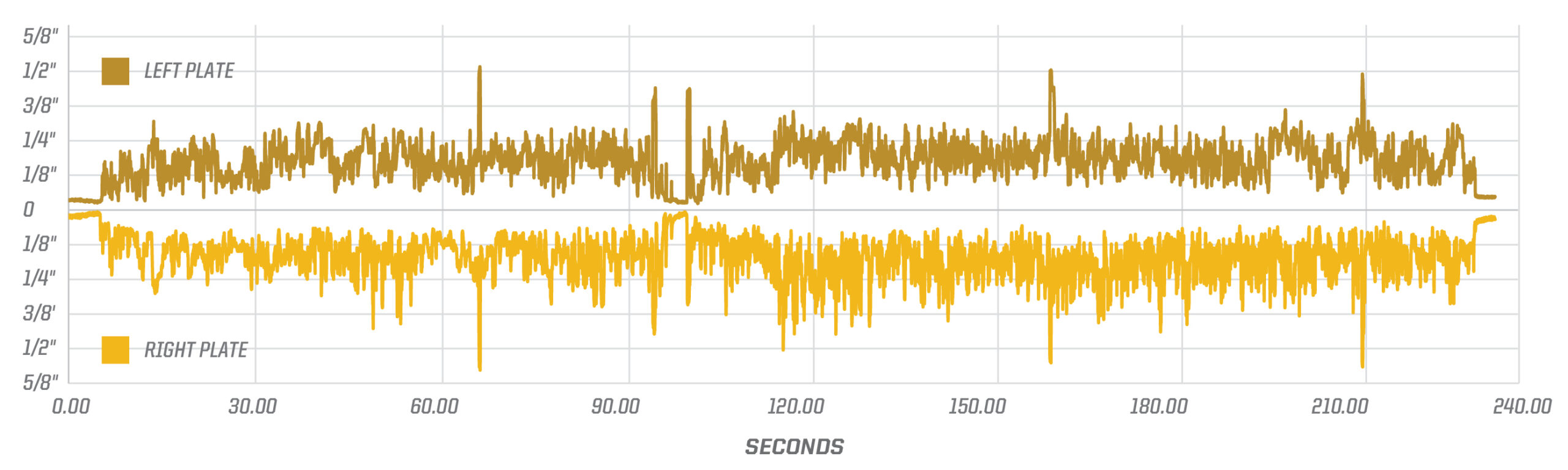

To substantiate this claim, Drago conducted three years of field research, attaching electronic sensors from Headsight® Harvesting Solutions** to the self-adjusting deck plates of a Drago corn head. The highly sensitive sensors measured the number and extent of gap adjustments made during harvest.

“Over the course of the three-year study, we uncovered more and more eye-opening data about how extensive stalk variability is within a given field,” Bollig explains. “We continued to refine our research over its course to validate the results.”

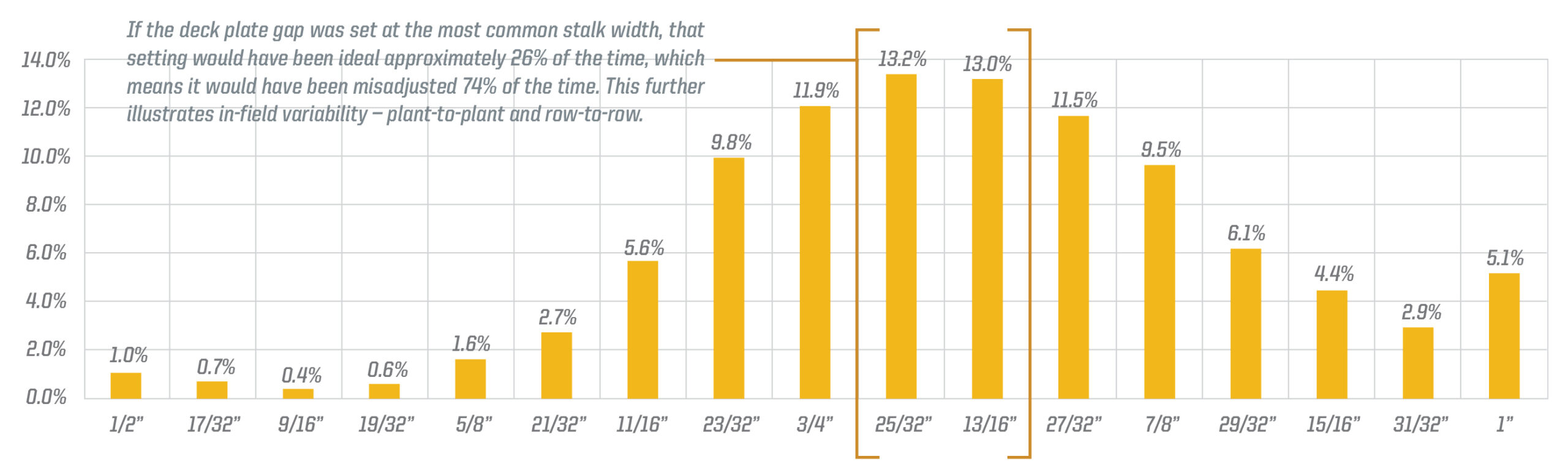

The study has consistently demonstrated that row-to-row deck plate gaps differ by 1/8 inch or more nearly 90% of the time. In higher-yielding areas, row-to-row deck plate gaps vary by 1/4 inch or more 40% of the time.

GAP DIFFERENCE BASED ON YIELD

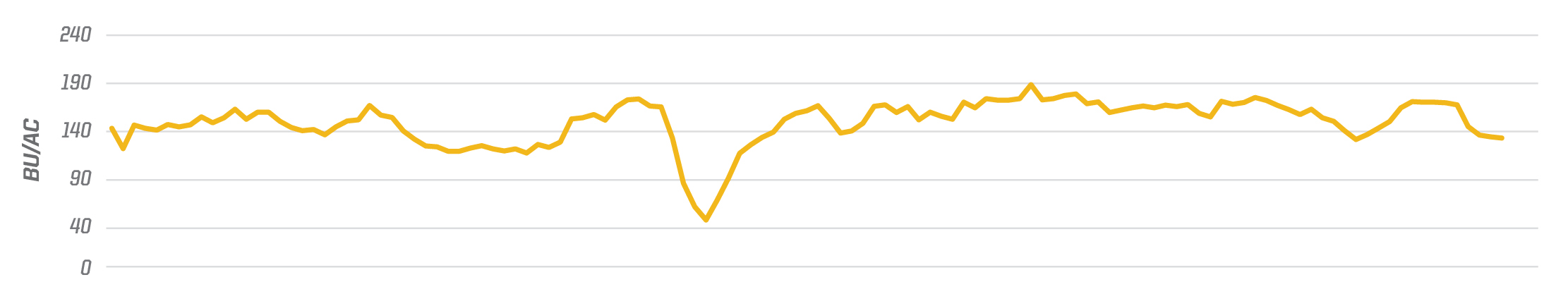

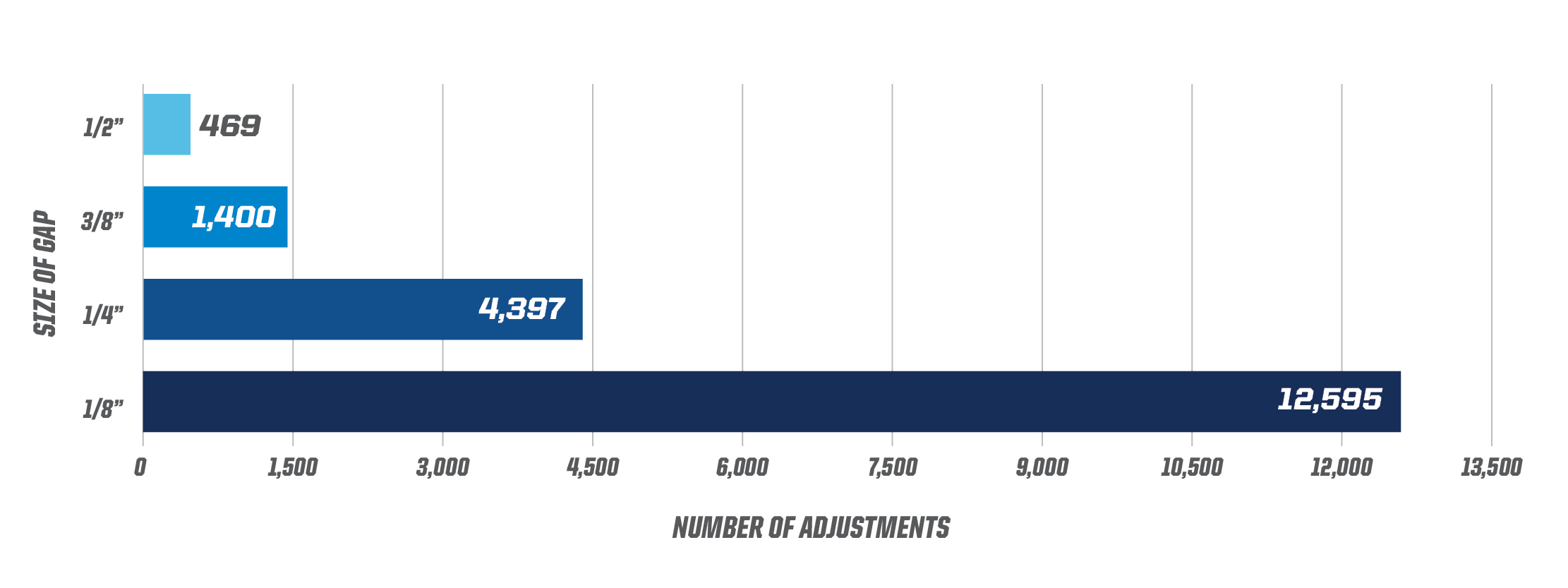

DECK PLATE ADJUSTMENTS/ACRE

Drago’s 2020 research revealed that its deck plates were making nearly two adjustments of 1/2 inch every second and 47 adjustments of 1/8 inch every second across the corn head.

“What we’ve seen is that the automatic self-adjusting deck plates deliver a significant improvement to manage gaps and capture more yield at harvest,” Bollig says. “Often, gap size differences were significant enough that a single deck plate setting across all rows of the corn head could result in small ear loss, let alone kernel loss.”